Products

| Laser Type | Fiber Laser |

|---|---|

| Cutting Speed | 140m/min |

| Cooling Mode | WATER COOLING |

| Control System Brand | Cypcut |

| Applicable Material | Metal |

| Condition | New |

| Cutting Area | 3000*1500mm |

| Place of Origin | Shandong, China |

| Laser Source Brand | IPG/MAX |

| Key Selling Points | Low Maintenance Cost |

| Warranty | 2 years |

| Applicable Industries | Other, Farms, Building Material Shops, Printing Shops, Machinery Repair Shops, Advertising Company, Manufacturing Plant, Construction works , Retail, industry, Energy & Mining |

| Mode of Operation | continuous wave |

| Configuration | gantry type |

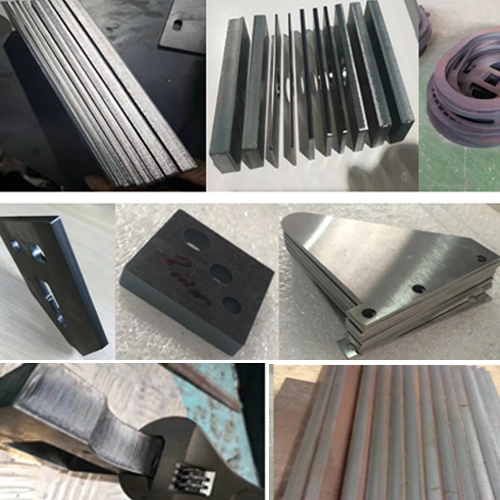

| Products handled | Sheet Metal |

| Feature | Fully-enclosed |

| Application | LASER CUTTING |

| Graphic Format Supported | BMP, AI, Dwg, DXP |

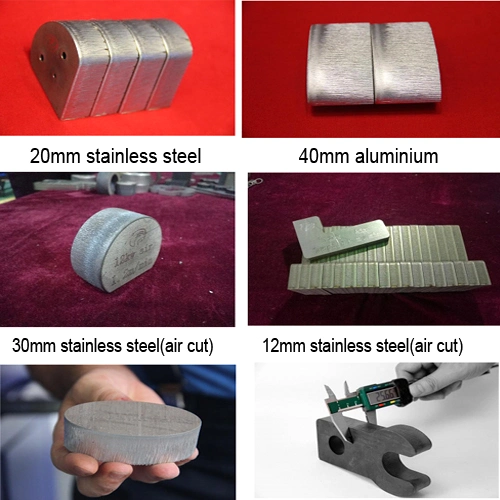

| Cutting Thickness | 0-80mm |

| CNC or Not | Yes |

| Control Software | Cypcut |

| Brand Name | Morn laser |

| Laser Head Brand | Raytools |

| Servo Motor Brand | Yaskawa |

| Guiderail Brand | PMI |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 2 years |

| Core Components | Laser source |

| Laser type | Fiber laser |

| Rated output power | 1000w-30000w optional |

| Effective cutting range | 1500*3000mm |

| Reposition accuracy | 0.02mm |

| Laser wavelength | 1080±5nm |

| Laser source | Raycus/MAX |

| Laser cutting head | Raytools |

| Control system | Cypcut |

| Oiling system | Automatic oiling system |

| Electrical requirement | 3 Phases 380V±10% 50HZ/60HZ |

| Package Type: | Standard wooden case for international trading |

| Supply Ability | 50 Set/Sets per Month |

Industrial Double Table with Cover Fiber Laser Cutting Machine 3000w 4000w 6000w 8000w 10000w 12000w 15000w 20000w

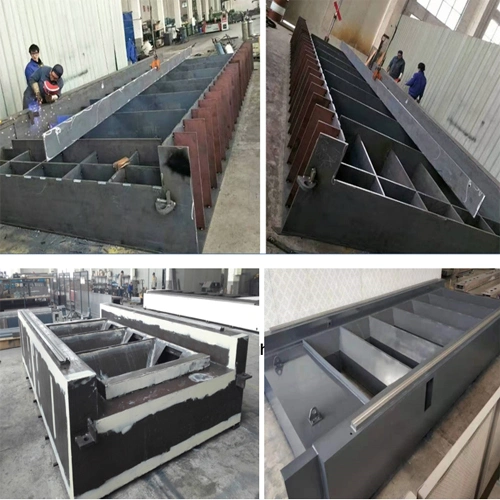

Machine Body (Plate welding with stiffener inside,not square pipe weld frame)

Square pipe welding frame table looks robust, but Pipe has distortion along with time goes. That's top brand machines body all are plate welding design.

Machines over 6 meters are welded with 16mm and 20mm steel plates. We promise that our customers' machine tools will not deform in ten years, and the quality is the best advertisement.

| Description | Technical parameters | |

|---|---|---|

| cutting size (mm) |

3000×1500/4000×2000/6000×2000/ 6000×2300/6000×2500 etc |

|

| The workpiece maximum height (mm) | 100 | |

| Effective travel | X axis(mm) | 6050 |

| Y axis (mm) | 2550 | |

| Z axis (mm) | 280 | |

| Cutting thickness | Carbon steel(mm) | 20mm(According laser power) |

| Stainless steel(mm) | 10mm(According laser power) | |

| Aluminum(mm) | 10mm(According laser power) | |

| Positional accuracy | X axis (mm/m) | ±0.06 |

| Y axis (mm/m) | ±0.06 | |

| Z axis (mm/m) | ±0.01 | |

| repeated positioning accuracy | X axis (mm) | ±0.03 |

| Y axis (mm) | ±0.03 | |

| Z axis (mm) | ±0.01 | |

| Rapid positioning speed | X axis (m/min) | 120 |

| Y axis (m/min) | 120 | |

| Z axis (m/min) | 60 | |

| Accelerated speed (G) | 2 | |

| Cutting Speed (m/min) | 80 | |

| Work table bearing(kg) | 5000kg | |

| Power consumption | 20kw/h | |

| Size L*W*H(mm) | 15510×3478×2106(for reference) | |

1.Why your machine price is higher, we have much cheaper offer from Jinan factories?

Our machine feature is robust table design like Europen brand machine with complete plate-welded structure, and heaviest in China.

You will check it out by real shipping weight!

We try to make high level machines that few factories can copy, because we have experienced engineers which are limited source in this field.

So if you don't have much cutting work, our machine is not cost-effective to you.

2. Can you produce the machine faster ?

As we need the machine urgently, High level machine is not simply assemble parts together and deliver it to customer. We don't do fast production. Long-termmachine stability depends on strict quality control. Inspection and testing work needs enough time if you to get long-time stable work machine.

We mainly rely on old customers recommend our machines to others to expand business. The machines we produced are best advertisement for us.

3. not offer 3 years warranty as Jinan factory?

Warranty service costs money if the supplier really do free service. We don't understand how can a company offer cheaper price and longer warranty at same time, unless the supplier just talk about it and play words game. because international parts delivery,air ticket…. not cheap at all, we do spend much money on service after sales, we seriously do as we said, you can check it with any of our old customer.

Without additional charge, we can not fulfil the responsibility of additional warranty.

4. How to choose laser power?

We suggest to choose laser power according to your main cutting thickness, no need to choose a bigger power for a cutting thickness less than 10% of total work. As far as we see,customer's business grows after using laser cutting machine, and need second or third machine along with business expand.

You don't need to make a big investment from the start.

High quality cutting is different from thickness cutting, you need to consider quality request,too.

Fastest

Installation

Top-Notch

Equipment

24/7 Customer

Support

100% Secured

Payment