_1724651718_WNo_1400d787.webp)

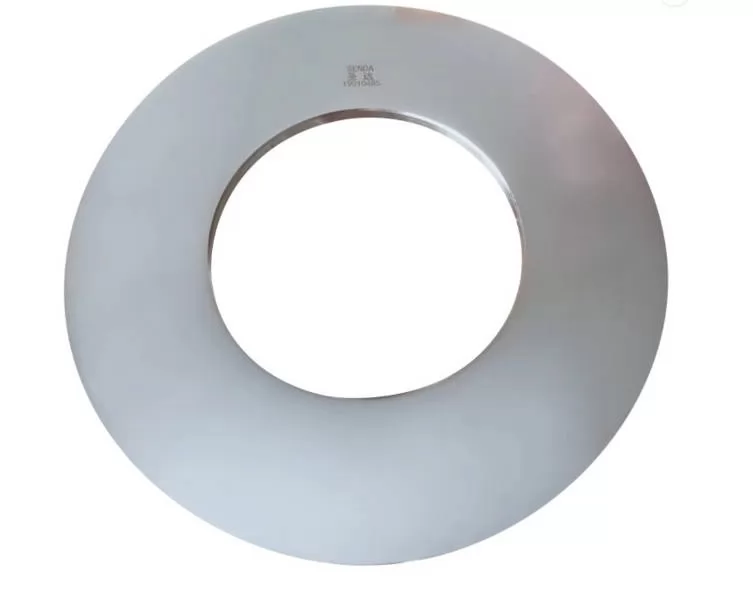

Slitter blade is an important part of the slitting machine equipment, mainly to slit the large rolls of material into different specifications according to the process requirements of small circle material. If the slitter blade is not properly chosen, it will reduce the precision and speed of slitting, consume raw materials, but also easy to cause slitting blade life shortened, increasing production costs.

1, slitting circular knife mainly has the upper and lower disc knife shear and circular knife extrusion type slitting two ways. Round knife slitting is slitting thick film, composite thick film, paper and other materials, the main slitting method. Slitting material film thickness of 100um or more recommended to use circular knife slitting.

2, the upper and lower disc slitting blade way widely used, mainly cut line slitting and non-cut line slitting two.

Cutting line slitting is more convenient, the upper disc knife and lower disc knife according to the requirements of the slitting width, easy to place to adjust the position. Its disadvantage is that the material is easy to drift phenomenon at the slitting, so the accuracy is not high, now generally not used.

Non-cutting line slitting can make the material less likely to drift, and the slitting accuracy is high. But the use of inconvenient, the lower disc knife installation, the need to remove the entire shaft. Round knife slitting is suitable for slitting thicker composite film and paper type.

3, round knife extrusion type slitting in the industry is not common in the field of application, it is mainly synchronized with the speed of the material and with the material has a wrap angle, the bottom roller and easy to adjust the pneumatic slitting knife composition. This slitting method can slit both thinner plastic film, but also thicker paper, non-woven fabrics, etc., is a more convenient way to slit.

Rotary slitter knives for coil processing line

1 Control the cutting force and cutting speed

Proper control of the cutting force and cutting speed of the tool is also an effective means to reduce the temperature of the processing area and extend the service life of the cutting fluid. When processing difficult-to-machine materials, generally use finely ground tool edges, cutting depth and cutting width should not be too large. When choosing the cutting line speed, it should be considered according to different material types, part structure and processing equipment.

For difficult-to-process materials, there is a great difference in the damage to the cutting fluid when choosing different cutting methods. No matter which cutting method is chosen, the principle is the same, that is, to reduce the cutting force and reduce the temperature of the cutting area as much as possible. The use of cycloidal plunge method can reduce the cutting area to a greater extent, so that the actual cutting fluid cutting angle to reach a smaller, thus extending the tool heat dissipation time per tooth, reducing the cutting temperature; the use of spiral interpolation method can make each tooth cutting volume relatively uniform, to avoid cutting force concentrated in a few teeth and accelerate wear, the effect is more obvious in the corner; and the use of large feed cutting method, with a smaller depth of cut, a larger feed to effectively reduce the damage to the cutting fluid. The large feed cutting method, with smaller depth of cut and larger feed, effectively reduces the cutting force and makes the machining produce less cutting heat and lower temperature in the machining area.

In metal processing, generally there will be a large amount of cutting heat generated on the cutting chips, if we can control the chip length and ensure timely and effective chip breaking, we can make this part of cutting heat taken away by the chips, so chip breaking is an effective way to control the cutting temperature. When machining difficult-to-machine materials, in the roughing process, under the premise that the rigidity of the machining system allows, it should try to make chip breakage throughout the machining process. Also use a cutting fluid with good sinking performance to sink the chips and discharge them, and do not allow them to rub against the surface of the machined workpiece. When mixed with water, it can form a stable and transparent solution.

Please contact Shinite to find more details, we will do our best to help you!

Fastest

Installation

Top-Notch

Equipment

24/7 Customer

Support

100% Secured

Payment