Steel Smelting

Exclusive Alloy Tool Steels by Shinite

Shinite specializes in producing blade materials such as 6CrW2Si, Cr12MoV, D2, SKD11, SKD61, H13, H13K, HMB, HMK, and other high-quality alloy tool steels. Equipped with a 1-ton medium frequency electric furnace and a 3-ton electroslag remelting furnace, Shinite independently smelts all these materials, surpassing national standards in alloy composition. Currently, we are the only blade manufacturing enterprise in China with our own steelmaking division.

Material Cutting

Round-the-Clock Precision

With 5 CNC saws, Shinite offers 24-hour continuous material cutting, ensuring uninterrupted material supply.

Forging

Enhanced Toughness and Density

Our forging process significantly increases the material's toughness and density, making it more robust and durable. With 5 air hammers capable of forging up to 4.5 tons of steel, we excel in traceability and problem analysis - a capability not commonly found in other blade manufacturers.

Rough Machining

Precision Controlled Processing

Our facility houses multiple lathes, drilling, and milling machines, perfectly controlling the excess material for better heat treatment and further precision machining.

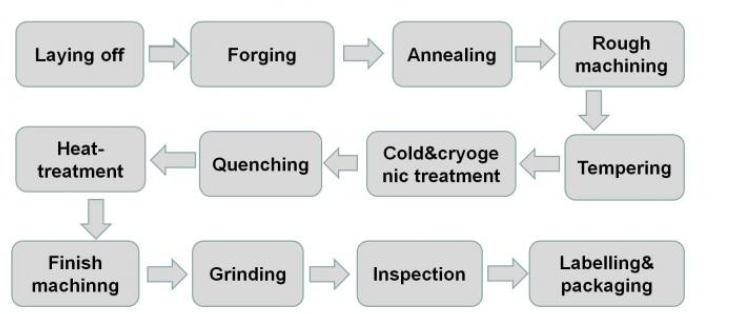

Heat Treatment

Enhancing Hardness and Toughness

Our blades undergo heat treatment in our workshop, equipped with 10 pit-type electrical resistance furnaces, box-type furnaces, and tempering furnaces, capable of treating blades up to 6 meters long.

Precision Machining

Advanced Equipment for Superior Quality

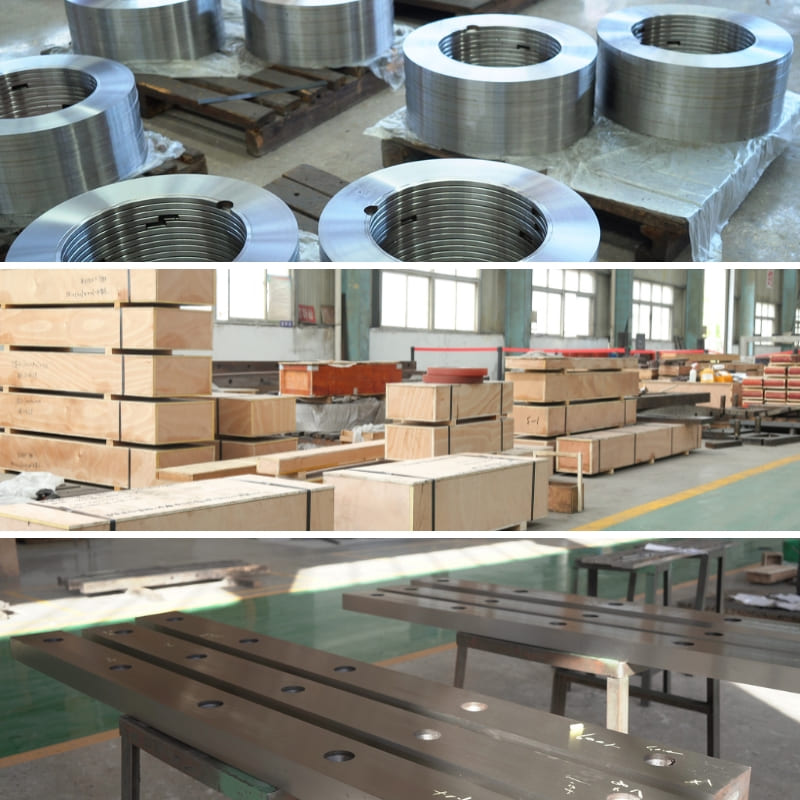

Shinite possesses over 60 sets of equipment including internal and external cylindrical grinders, surface grinders, CNC grinders, and EDM wire-cutting machines, capable of producing shearing blades up to 5500mm in length and slitting blades with a diameter of 1500mm.

Inspection and Packaging

Ensuring Quality and Safety

Our extensive range of testing equipment ensures that all blades meet drawing specifications. We use custom-made wooden crates for packaging, ensuring the products reach our customers without damage or rust.

.png)

.png)

.png)

.png)

.png)